The Challenge of proper lubrication has been an issue since the beginning of the industrial age. The impact of proper lubrication in the rotating machinery domain is significant. It is commonly agreed that about 80% of the root cause of failure trace back to lubrication.

However, many rely on the calendar-based interval in greasing routines. This might be mainly as there have not been easy alternative ways to detect and manage this.

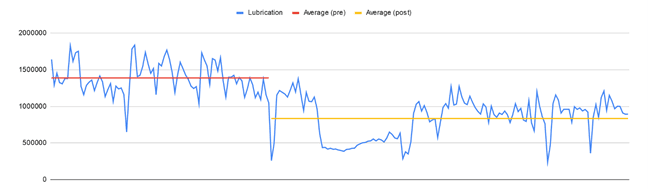

Condence Introduces a lubrication indicator. The trend of this value makes it possible to keep track of the level of lubrication by measuring the change in the friction level.

The maintenance team can see the level of lubrication indicator and set a notification on desired point level to get a notification from the system when lubrication is needed and see the change in value and make sure that the action was effective.

In case greasing as a first-aid does not provide the desired result double-check the lubricant used or follow more closely if potential damage is in play. Situations where the increased absolute level of lubrication indicator has indicated bearing damage that was visible in envelope analysis several months afterwards.

The feature is based on scientific research conducted by the University of Oulu Intelligent machines and systems research team. Method of signal processing is the foundation of the feature and it has alternative use cases in friction detection e.g on slowly rotating machines and plain/ sliding bearings. These applications are also available in Condence and configuration is accessible for administration-level users, ask more from your vendor.

Panu Kinnari / COO

0 Comments