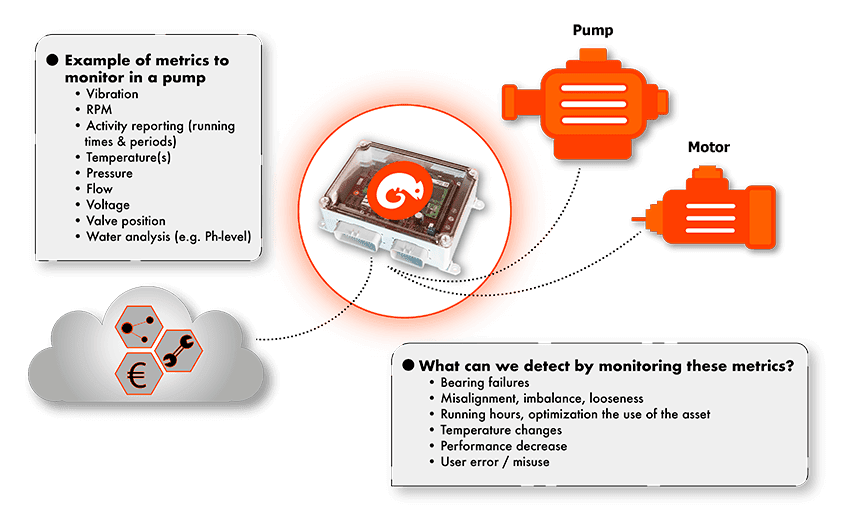

Condition Monitoring of a Pump

From reactive to predictive maintenance

When a pump fails without warning, the unplanned downtime and deployment of maintenance staff-related costs and resulting in loss of production will disrupt any operation, particularly if the pump is serving as a critical asset.

Because of their critical tasks, many industrial pumps and electric motors are commonly inspected frequently. However, this type of condition monitoring only gives a “snapshot” of the machine’s health.

Online condition monitoring makes it possible for companies to move from reactive and highly manual maintenance strategy to predictive and preventive maintenance strategy.

The central tenet of predictive maintenance is the detection and resolution of failures before they occur through observation of the actual conditions of the machinery.

As an example, the repairs and services of your fleet of pumps aimed at restoring performance, are executed when they are actually necessary.

Real-time condition monitoring brings you valid and accurate information for decision making. It enables you to optimize productivity in several ways.

Please use the links below to learn more about the Condence platform!

CONDENCE GEARBOX

Read more

CONDENCE FAN/BLOWER

Read more

CONDENCE BEARINGS

Read more

CONDENCE OIL

Read more

CONDENCE COMPRESSORS

Read more

CONDENCE ELECTRIC MOTOR

Read more

BACK TO APPLICATIONS

Read more

BACK TO PRODUCTS

Read more