Compressor condition monitoring

Condition monitoring of compressors

with Condence

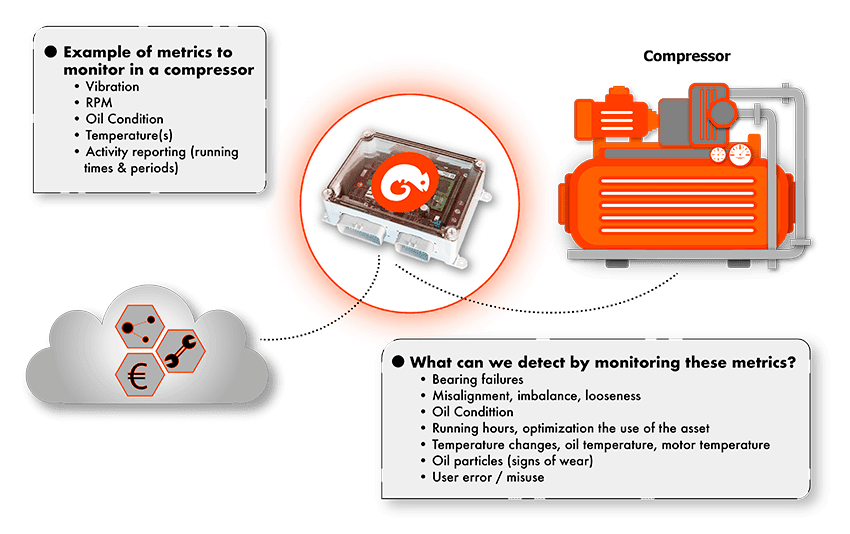

Compressors are utilized in various roles throughout industrial sectors and production facilities. The constantly increasing reliance on compressors requires a high level of reliability to meet production demands. Topics like maximum reliability, maximum capacity, maximum efficiency and minimum operating and maintenance costs underline the importance of proper maintenance strategy to be in place. Condences flexibility, versatility and online capabilities make it the perfect solution to monitor the condition of compressors. Vibration analysis is a tested and proven method for monitoring compressors, but it´s not by far only thing Condence for compressors can offer.

Ability to adapt

Compressors come in different types, shapes and designs, which means “one size fits all” approach is out of the question. With Condence you can select from a wide range of different types of sensors to source vibration and then create any analysis you want for those sensors from the Cloud UI. However, often the preferred sensor type is IEPE due to its wide frequency range. Wide frequency range translates into time to react, so it is not a thing you can afford to waste.

Another strong point of Condence is its vibration analyses. Once the physical installation is done, you can do all the rest in Condence cloud portal. Whether the wanted analysis is frequency or time domain you can create, change and manage them in a purpose-built configuration UI. You can manage the measurements done on each channel, what is being measured, how often and how often it is reported to the cloud. The terminal makes the measurements and analyses on the edge and send only the relevant data to the cloud. You can, of course, subscribe to get raw data samples too, if necessary.

Multi-functional solution for a

multi-functional metric

Vibration analysis is not the only method relevant to condition monitoring of a compressor. Compressors oil carries a lot of valuable health data in it and is too valuable health parameter to be ignored. In compressors the lubricating oil is multi-functional, it protects the compressor from leaks, lubricates moving parts and stabilizes temperature during operations. Monitoring and managing the lubricant condition can prevent costly breakdowns and optimize the costly time-based routines. Oil analysis of compressors oil has been a manual task for decades, but with Condence you can monitor several different metrics of the oil constantly, instead of snapshotting scheduled samples. With Condence solution the health data is collected from the oil line continuously and is available 24/7.

You can also get data from other metrics, Condence for compressors can be connected to thousands of different types of sensors, giving you secure web-based data access through a simple web browser, visible on a computer, tablet or smartphone. Terminals are fully configurable from cloud UI and you can create, adjust and set alarms to any metric to get notified if set thresholds are exceeded.

Please use the links below to learn more about the Condence platform!

CONDENCE PUMP

Read more

CONDENCE FAN/BLOWER

Read more

CONDENCE BEARINGS

Read more

CONDENCE OIL

Read more

CONDENCE GEARBOX

Read more

CONDENCE ELECTRIC MOTOR

Read more

BACK TO APPLICATIONS

Read more

BACK TO PRODUCTS

Read more