Bearing condition monitoring

Condition monitoring of bearings with Condence

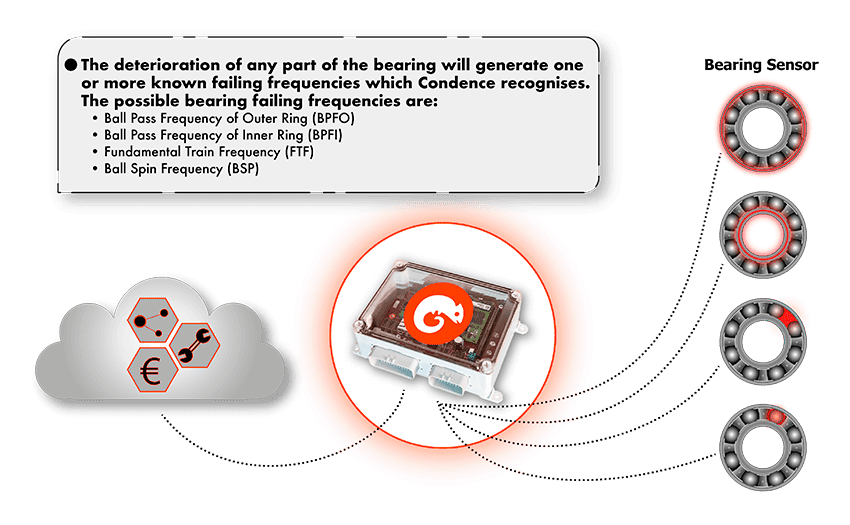

Bearing failures are considered to be one of the most common types of failures for rotating machinery. Sudden bearing failure can lead to a complete machine breakdown, force the entire process to be shut down causing production and financial losses. This is the reason why it is vital to have proper bearing condition monitoring in place. Condence high-frequency vibration monitoring detects the faults when they are still microscopic in size and there is plenty of time to react. Wear, cracks and spalls appear initially on high-level frequencies, extending into lower frequency vibration as the fault becomes worse. When measurements are performed with the proper type of sensors like IEPE/ICP which are capable of detecting high frequencies, there is plenty of time to react and plan the optimal point of repair case by case.

Condence solution makes bearing vibration data collection and the analysis extremely efficient and easy in a sensor-to-user interface, a fully integrated independent tool. It makes health monitoring of bearings free from time and space, freeing critical resources to more productive work.

With Condence, you can automatically detect early fault indicators, and once detected, automatically follow the trend of any calculated value and set required alarms. Advanced analysis tools are at your disposal, anywhere and anytime. You avoid repeating frequent manual inspections, buy time to plan and react – in sum, increase operational excellence.

The implementation of Condence for bearings is made simple. In most cases the installation does not require any interruption to the process, the configuration is done through the online user interface on the Condence web tool and firmware, new algorithms and other software updates are done remotely.

Please use the links below to learn more about the Condence platform!

CONDENCE PUMP

Read more

CONDENCE GEARBOX

Read more

CONDENCE FAN/BLOWER

Read more

CONDENCE OIL

Read more

CONDENCE COMPRESSORS

Read more

CONDENCE ELECTRIC MOTOR

Read more

BACK TO APPLICATIONS

Read more

BACK TO PRODUCTS

Read more