Remaining time to service – Extent Remaining useful life

Machine lifetime or the remaining useful life of a device often depends on the maintenance actions made during the lifecycle of a machine. Condence time to service tool will help on allocation and optimising intervals of planned actions.

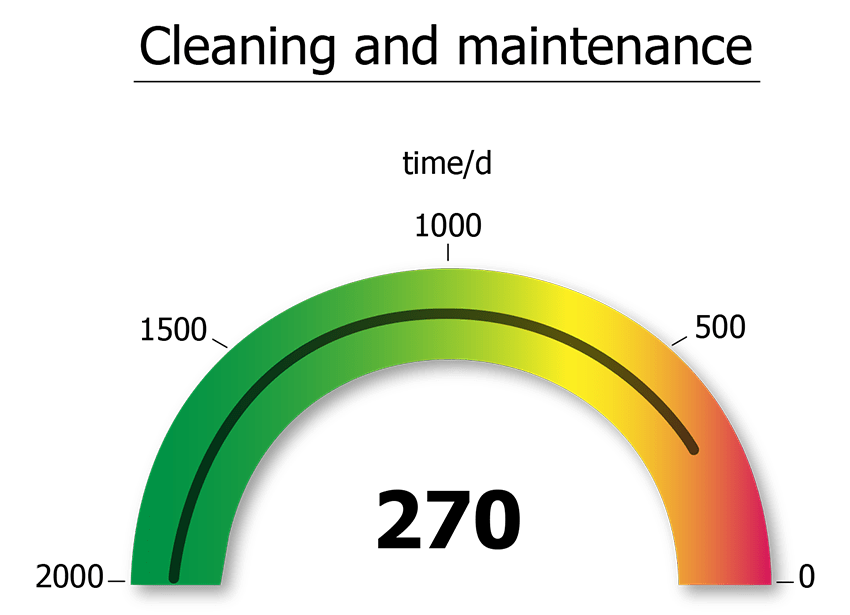

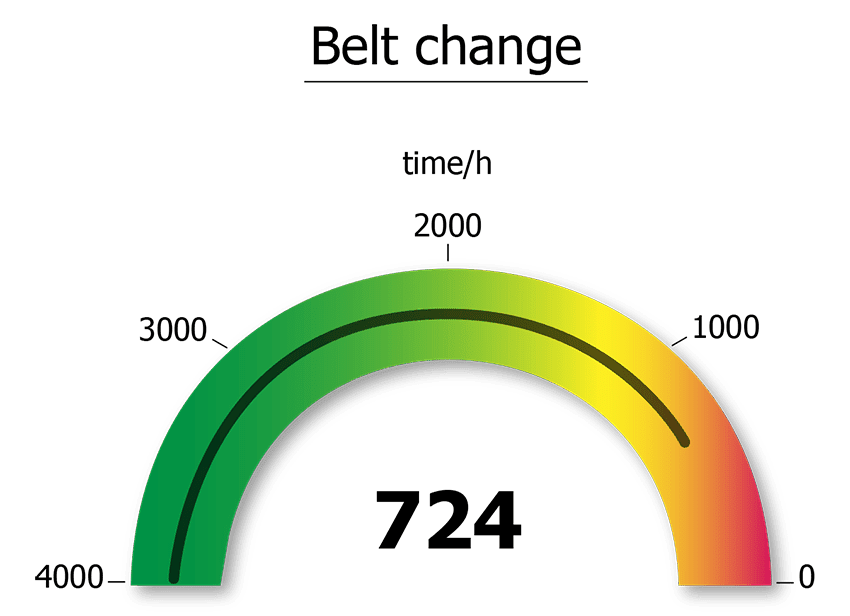

There is often a difference between calendar-based schedules and running hours. The most straightforward way is to estimate the time left for the next inspection. It is visualized and communicated in a clear way. You can set alarms & notifications including custom messages, and instructions to the values.

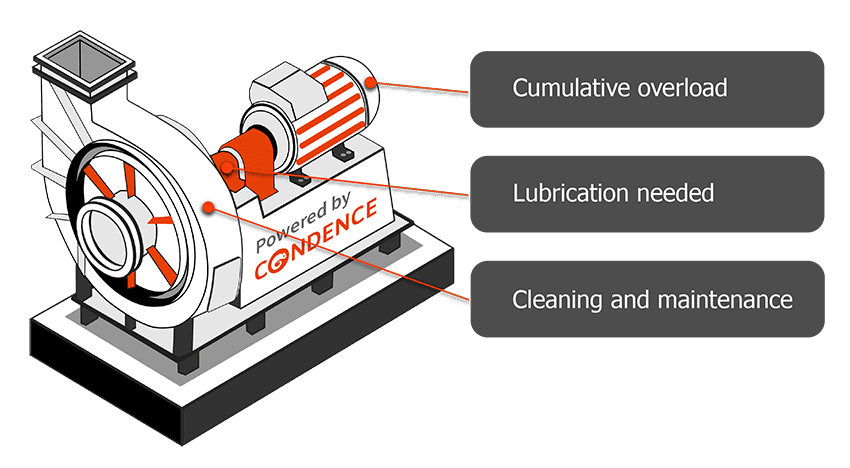

Time to Service toolkit has three different components:

• Time used

• Estimated time left

• Cumulative time

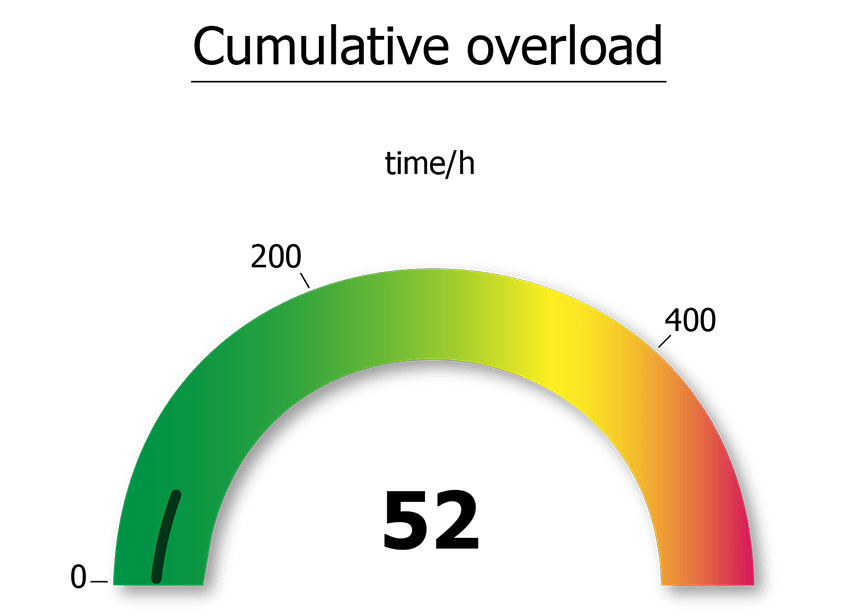

While it is possible to use the tool as a simple cumulative running time calculator & notifier, the true power is in more advanced methods. Different service needs emerge based on how machines are used. In the pump example, the need for filter chance might depend on flow rate, and overloading situations might lead to inspection need, oil temperature to an oil change, and other typical wearing components on time used in a specific state.

An example of wearing components days left to service is estimated based on typical daily use patterns, and the system gives an estimate of days left of usage. Notifications and instruction messages can be connected to, e.g., 50 days to order spare parts and another ten days to schedule this task. If integration to CMMS/EAM is used, an automated service request with instruction can be opened.

The active use service schedules and intervals can be optimized and viewed for more efficient and precise maintenance planning and potential preparation. The estimation will give an outlook for timing where usage will expose many needs typically detected by visual inspection.

We have more features to come on how to maximize machine health. The following upgrade tool will be released later in 2022, allowing more dynamic forecasts and predictions.

Panu Kinnari

Chief Operating Officer

panu.kinnari@distence.fi

0 Comments